- STEP 1

- Uncovering customer needs

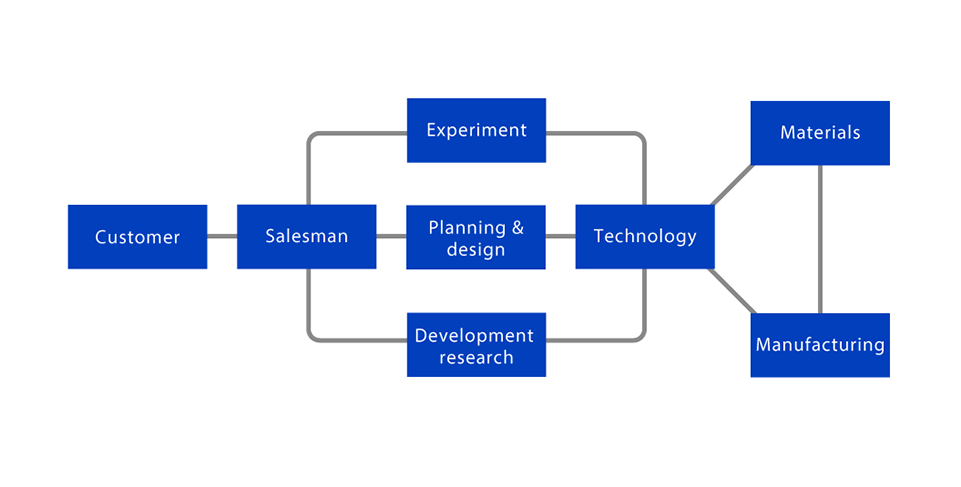

Our sales staff will support you regarding the needs at each stage of research, development, and planning for the introduction of equipment.

We have been playing a part in our customers’ new product development with our coaters, dryers, and other products, as well as our coating and floating drying technologies using them.

There is no limit to the clients’ wish to bring better products to the market.

We will continue to make full use of our state-of-the-art coaters, dryers, and other equipment, as well as our experience-based know-how, to realize customers’ desire to create their “ideal products”.

Please feel free to contact us.

Our sales staff will support you regarding the needs at each stage of research, development, and planning for the introduction of equipment.

We will propose “coating and drying requirements” based on our long-accumulated experience and drying simulation technology in response to customers’ requests.

We will be as flexible as possible in cases where modifications to the test equipment are required to recreate conditions that are closer to those of the actual equipment. Also, please contact us for testing machines that require high quality, such as “corona treater,” “UV equipment,” “static eliminators,” “liquid feed pumps,” and “deaerators”, without hesitation. We handle a variety of tests flexibly by making full use of our strong communication network.

We will determine the date of the experiment. To make the most of the limited time available on the day, we will provide suggestions on experimental content and procedures.

Our experienced staff will take care of everything from preparation, operation, and cleanup of the test equipment to compilation of data, so you can concentrate on confirming your experiments.

If you are satisfied with the sample, we will reflect it in the design conditions of future research, development, and production machine manufacturing, etc.

The following are examples of new product development tests for our customers conducted in the past that involved episodes that are especially noteworthy.

You will see that “the process of creating new products, even those that lead and innovate the market, actually involved instances that make you smile.

The “ultra-low speed” test at 0.1 m/min resulted in one sample taking an hour and a half to complete….

Both the customer and our staff found it extremely difficult to kill time during the sample test.

In a development experiment requested by a company, we had to handle 1 L of coating liquid that is extremely expensive.

Although we were quite prepared for the experiment, we were simply nervous on the test day.

I still vividly remember to this day breaking out in a cold sweat when handling it.

In a certain product test, there was a requirement that “the sample must not be exposed to light because it causes deterioration.”

Since the request was made in August, when the daylight hours are long, we decided to start the experiment at 8:00 p.m….

Even though the use of light was prohibited, the staff could not move without any light at all, so the test was executed with three or four red lights on.

However, as expected, we could not see things clearly, and it was very difficult to conduct the experiment without a hitch.

After all the hard work, we were finally able to submit something that satisfied the client. Now it is a good memory.